Precision Handling: Lower Units, Mounts, Steering

One of the biggest safety and performance considerations for any high performance boat is high speed handling, and although the hull design is critical to handling, the setup is vital. Old school sport boats often had dual cable steering, engines with solid mounts, and the engine positioned as high as possible. Cable steering allowed for very precise steering feel, however you would have to have the forearm strength of a Russian powerlifter. Even though modern power steering systems make steering smooth, it doesn’t always mean they are precise. You need to have extremely precise steering to operate at high speeds safely, and you have to have your engine mounted high enough where drag is reduced, yet the prop can still carry enough water. Engine height, gearcase shape, the prop and the engine mounts are critical pieces to consider when setting up. Let’s take a look at each of them and why it’s important. For Sterndrives, the same general principles apply.

The Lower Unit

Even though bullet nose lower units, crescent shaped designs were once reserved for the ultra high performance crowd and racing, you now see them often on semi performance outboards geared towards bass boats, bay boats and center consoles. The characteristics of a high performance lower unit are that they can be run much higher than a traditional gearcase, and utilize low water pickups on the front of the nose cone, or even have separate water pickups in order to maintain water pressure. In effect, the water flow around a more streamlined lower unit is better when speeds exceed about 80 or 85 MPH. A traditional blunt gearcase begins to cause too much water disruption when speeds in the 85+ MPH range are seen, depending on the design.

Lower

Gearcases come in many shapes, the famous Sport Master from Mercury Racing is designed for running in excess of 85 MPH, with the engine mounted high.

But that doesn’t mean a nose cone or high performance lower unit is better for your boat, in fact if you’re not running over 80 MPH, it can slow you down, or if you’re prop is too submerged, the lower unit won’t be utilized properly.

The key benefit is being able to elevate your engine / prop as high as possible, which improves efficiency at high speeds and handling. When you have your engine that high, and at speeds over 80 MPH, you will benefit from the improved water flow around the gearcase, allowing your propeller to capture as much water as possible, while breaking the water surface.

Again, a traditional lower unit will not be able to be raised high enough without compromising water pressure, and water flow to the propeller with speeds in excess of about 80+ MPH. If you’re running less than that, you can still benefit from low water pick ups, and maximizing the height of your engine. Depending on the boat, you can sometimes gain 1 MPH per inch of increased height, and usually about 100 to 150 RPM per inch. Prop selection becomes critical running at elevated prop heights. But the next critical thing is precision.

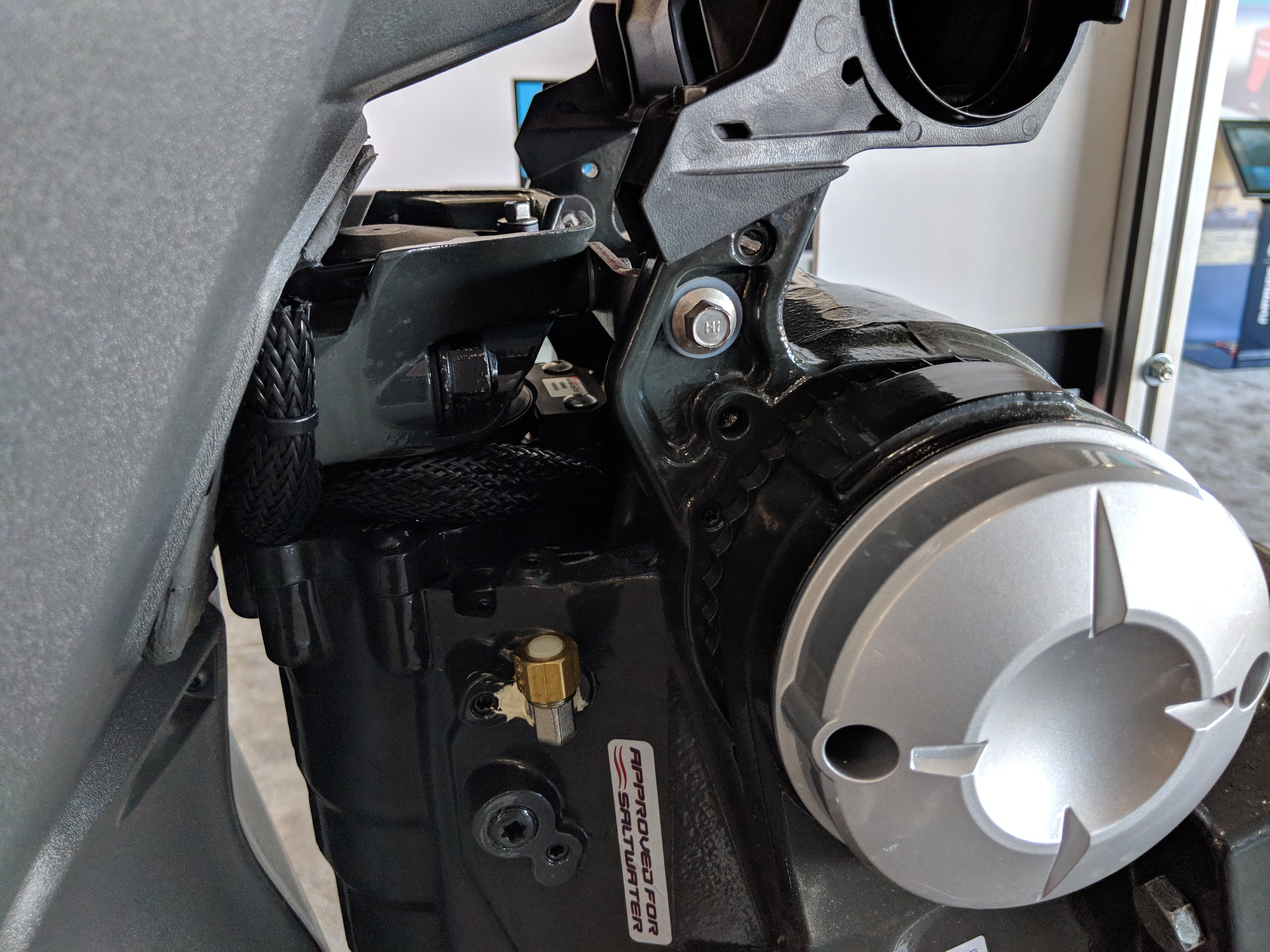

This is a fairly performance orientated lower unit, seen on this Suzuki 300. The big fishing and center console boats are getting faster and faster. Nice engine with a bullet nose, low water pickups, but a little heavy for real performance use, and sloppy mounts. Looks cool though.

Mounts

Motor mounts, in terms of outboard engines, determine how precise your boat will handle, or more specifically, how much play there will be between the mounting bracket and the actual engine. This is so important, because if you have a really nice steering system, but your mounts are traditional rubber mounts that are designed to absorb vibration and shock, you will experience sloppy handling. This movement of the engine in extreme conditions not only causes handling issues but causes excess wear on the transom, steering system and is less safe overall. Plus, rubber mounts degrade over time. Not only will you feel the slop in rubber mounts, you can see the engine wobbling all over, which gets progressively worse as the rubber breaks down.

The Evinrude G2 has a unique bracket with integrated steering and all rigging in one tube. However, the mounts are what really make or break a good steering system. Mounts with play will hurt handling at high speeds. Unless your engine is from Mercury Racing, your mounts are probably a weak link.

Solid mounts can cause vibration, but that is about the only negative. Most solid mounts are aluminum or delrin, which is a highly durable thermoplastic. Semi solid mounts are popular and are usually a polyurethane or other dense rubber. Many engines have the upper and lower mounts in an encasing, uppers under the powerhead, and the lowers attached at the bottom of the mid section. When you are balancing a boat on its pad or holding steady at high speeds, you need precision handling. Any slop means you will be working the wheel too much, causing less control, drag, and other adverse effects. In rough water, it is really bad (check the video below).

Some modern engines have unique mounts, like the Mercury Verado, which move directionally front to back, not laterally, which is smart to prevent side to side play. Others are clamp style, enclosed mounts that try to find the balance between stiffness and absorption. For high performance applications, even modest, solid mounts would be one of the first things I would recommend as an upgrade. They are simply the most basic and critical upgrade that will affect your steering and handling.

Steering

We have a set of articles dedicated to steering for outboards and one for sterndrives, so here I just want to mention a few things. Front mount hydraulic steering for outboards has been around for a long time but for hardcore performance boats it was not adopted as quickly because early systems had quite a bit of play in the system. Eventually, manufacturers began making systems with special lock valves, short lock to lock turns and robust helms to make them very precise, yet safe as they make it effortless to steer at high speeds. Front mount and side mount hydraulic steering are great, but can be hampered by bad mounts.

A Bob's Machine jack plate, powder coated in white, with a popular Uflex steering system. The ability to adjust engine height on the fly is ideal on most performance boats. Proper steering allows for better and safer control at high speeds.

Setback and Height

Another aspect of handling is how high you are running your engine and how far it is setback from the transom. In another article about weight dynamics, we talked about how the engine height can affect dynamic center of gravity, raising it moves dynamic CG forward, by reducing drag essentially. But, moving your engine further also moves static CG further back. Setting the engine back also allows you to raise the engine a bit higher, can help bow lift and moves the lower unit away from the transom.

The hull design, weight of the engine, and use case all determine how much setback you might run. This Checkmate 2400 can use lots of setback and handle the weight of a heavy engine.

What is complicated is there are several factors that will determine what is best for your boat. Your hull design, weight of your engine and your intended use all contribute to how you might set it up. Lighter engines will almost always allow your boat to handle better, and don’t disrupt CG as much when setback on the transom. Hulls with notches built into the design, already have “setback” so often don’t need major extension brackets or extended jack plates. A really wide pad on a V hull can handle more weight, and often more setback.

Naturally, testing is the ultimate proof though and many hulls have different characteristics based their own weight distribution and design. Some smaller boats can’t handle too much weight set far back and will display bad handling characteristics like porpoising and chine walking. Other hulls, like Mod VPs and tunnels need to run flat, with no positive trim but the engine mounted extremely high. Test what you can incrementally, while keeping these general principles in mind. This is just an overview and not meant to be comprehensive, just to serve as a guide to get started on setting up your boat.

This is a Seven Marine crescent shaped gearcase for extreme use. You can see the low water pickups under the nose cone. Serious big boy pants required.

Many tunnels run with the engine set high, and often have a more set it and forget it approach. This MTI 340X with a fixed bracket, set to an optimum height and not much setback.

Here is what old rubber mounts perform like.

Rubber mounts in action on this Active Thunder 22 Banshee, watch it move. Yamaha has notoriously bad mounts. Very cool boat though.